From recycled plastic collected in household recycling sacks directly to high-quality shower gel bottles - the companies Werner & Mertz, Systec Plastics Eisfeld and EREMA managed this demanding recycling and production task in May 2019.

Thanks to state-of-the-art recycling technologies and close, cross-company cooperation, the first 100 percent recycled plastic packaging for a body care product made its way onto the shelves. The EREMA technologies INTAREMA® TVEplus® RegrindPro® and the ReFresher module, which ensure the required high regrind quality, including the necessary odour optimisation, play a major role in this success.

Plastic pellets from post consumer material

In an effort not to turn used plastics into waste in the first place, but to recycle them, the production of high-quality recyclates is becoming increasingly important in addition to avoidance and recycling strategies. This involves making plastic pellets from used and contaminated post consumer material, which is used again in the production of new plastic products. Although the processing of household plastic packaging is a challenge in recycling terms, thanks to technological advances and resourceful manufacturers, recyclates now meet quality criteria almost as high as virgin material and can therefore be used in almost as many ways. Just how diverse the fields of application for recyclates have become can be seen at Systec Plastics Eisfeld GmbH (SPE), an EREMA customer in The Group with the Green Dot.

World first in the cosmetics sector

The raw material for Systalen, the brand name for their recyclates, is plastic waste sourced from what is known as the dual system, which is packaging material collected from households in Germany. Depending on the product, plastics are processed that meet the required specifications and are of the same type. "They must have a high and reliably consistent quality, be colour-neutral and almost odourless," says Dr. Markus Helftewes, Managing Director of SPE, explaining the basic requirements that must be fulfilled by recyclates used to produce new high-quality consumer goods.

The bottle for Frosch Senses brand shower gel launched in May 2019 had to meet particularly stringent requirements. This bottle is the first packaging used in cosmetics to be made with 100% recycled HDPE collected in from household recycling sacks - a world first based on the cooperation between Werner & Mertz, the manufacturer of Frosch brand products, The Group with the Green Dot and EREMA.

"Recyclates must have a high and reliably consistent quality, be colour neutral and almost odourless."

Innovative technology for the highest possible quality

"The great challenge in developing the production process for these shower gel bottles - apart from attaining the required functional properties - was the washing process, which cleans the material not only of dirt and foreign matter, but also of odours. That's why a special method is already applied during washing", says Helftewes. The next stages in processing the washed flakes use EREMA recycling technology. The INTAREMA® TVEplus® RegrindPro® extruder system has been specially designed to process post consumer material following the addition of the laser filter and ReFresher module. The system is an absolute all-rounder regarding the materials it can process because the wide spectrum of input bulk densities it can handle - from 30 to 800 g/l - makes it suitable for flakes as well as for regrind, film and nonwoven applications. The feed material is gently heated mechanically in the Preconditioning Unit for a period of one hour, flushed with air and then during this process step it is degassed for the first time. The melt filtration using the laser filter takes place before the extruder degassing, and the laser filter used here can handle impurity levels of up to five percent. Finally, the ReFresher removes other odour substances from the pellets.

"The ReFresher makes use of the latent energy generated by the preheated pellets during the extrusion process. This really saves energy.”

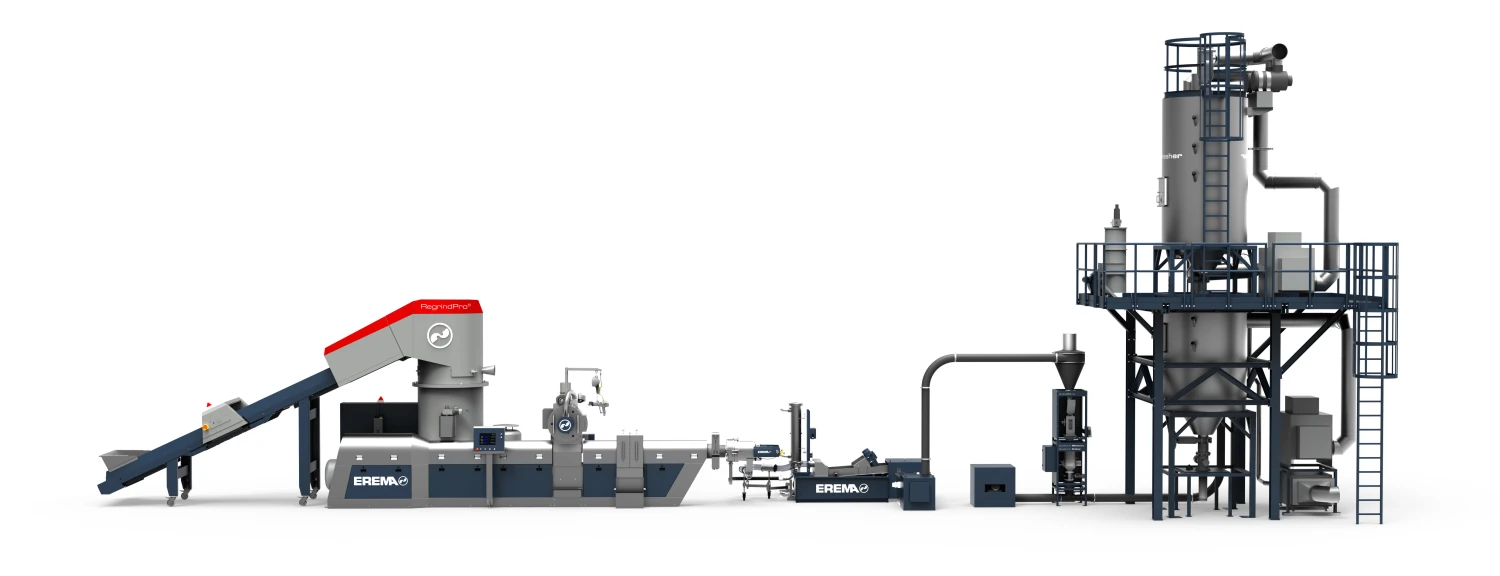

Efficient combination of technologies for high regrind quality and odour optimisation: The INTAREMA® TVEplus® in RegrindPro® design extruder system with subsequent ReFresher module.

Cooperation enables circular economy

That 100 percent recycled packaging has been developed for the first time for a body care product - subject to the strict requirements of the cosmetics sector - is the result of the dedicated cooperation of the companies involved, says Clemens Kitzberger: "It's good that there are such innovative companies with whom we can jointly promote recycling. This sends out an important message to the entire plastics industry!"

"For us, this shower gel bottle is another milestone in the implementation of our recyclate initiative.”

The aim of this initiative is to make recycling materials collected from households usable for the production of new packaging.

(article 01.10.2019)