As the demand for recycled plastics grows, so does the size of the machines. This applies to the processing of polyolefins as well as to PET recycling. The new models of VACUREMA® Basic technology are unique in their scale and production capacity. With a throughput of up to six tonnes per hour, they also consume ten percent less energy than comparable systems without the new EcoGentle® plasticising technology, which EREMA will be presenting for the first time at K 2022.

In the PET recycling segment, EREMA proved its expertise as a partner for unique large-scale recycling projects several times last year. At the end of 2021, the recycling machine manufacturer delivered a large-scale VACUREMA® Basic 2628 T plant for the first time with a production capacity of up to 40,000 tonnes of rPET granulate per year. Since then, throughput capacity has again been significantly increased. "Up to six tonnes per hour are possible with our new plasticising technology," Michael Heitzinger, Managing Director at EREMA, points out. The recycling machine manufacturer calls this plasticising unit EcoGentle® because it significantly reduces energy consumption. Measurements on a VACUREMA® Basic 2628 T system resulted in up to 12 percent total energy saving (specific total energy consumption, kWh/kg) and 30 to 47 percent energy saving for the extruder drive on VACUREMA® Basic plants from size 2021 upwards. Additionaly EcoGentle® handles the melt in an impressively gentle way. At the same time as achieving unprecedented high throughputs. "All in all, this is a package that enables our customers to increase productivity and noticeably reduce costs," says Heitzinger.

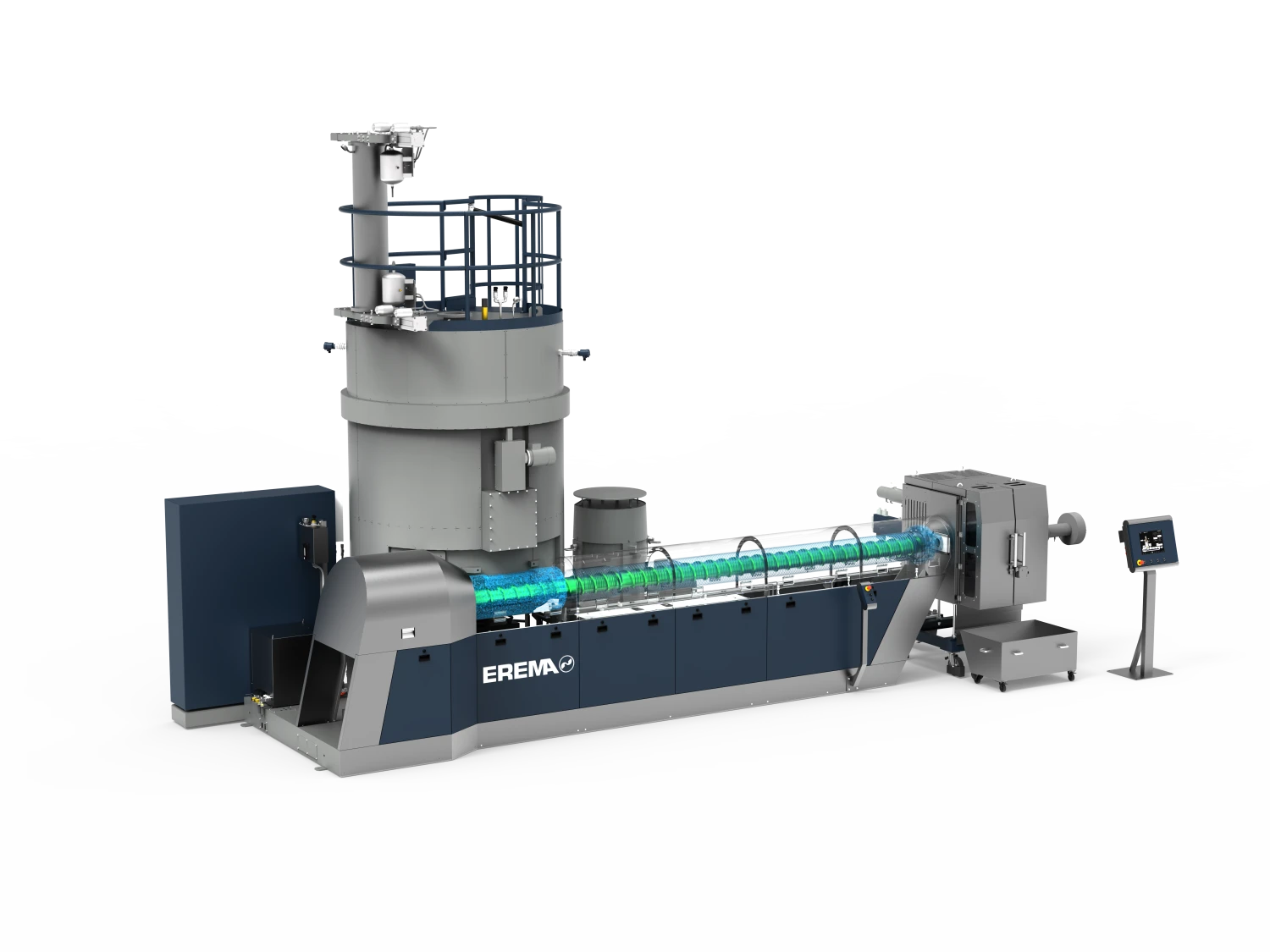

The new EcoGentle® plasticising unit from EREMA. The gently way to highest throughputs. Photo: EREMA GmbH

The decisive factor here is the further perfected interaction of the intake section and extruder screw as a result of the combination of the EcoGentle® plasticising unit with the proven Counter Current® technology. The optimisation of compression ratios ensures better feeding performance, and the selective exploitation of elongation flows, together with a number of other rheological optimisations, results in a particularly homogeneous melt and a wider process window. This makes it even easier to compensate for fluctuations in the input material without negatively impacting process stability. Due to the significantly lower temperature, the melt is processed more gently overall. The result is even lower acetaldehyde (AA) values, which translate into producing even higher quality rPET pellets.

This development is also based on the know-how bundled in the EREMA Group. Essential core components for EcoGentle® are manufactured in Austria by 3S, one of EREMA GmbH's sister companies.

Currently, EREMA's large-scale plant focus is on PET recycling. But it will not stop there, because the recycling machine manufacturer is already working intensively on upscaling the technologies for polyolefin recycling to achieve high throughput volumes. "The push for a circular economy demands it, and we will deliver with our usual quality and reliability," confirms Heitzinger.

Download Presseinfo als .pdf:

Download Bild als .jpg: