Edvanced Recycling - EREMA prime solutions for advanced recycling. This is the tagline announcing EREMA’s launch of innovative products and technologies for plastics recycling at K in Düsseldorf from 8 to 15 October 2025. One of the many highlights is the INTAREMA® TVEplus® DuaFil® Compact double filtration system, which is live, in action, processing eleven different post consumer materials to make high-quality recycled pellets at the Edvanced Recycling Centre. EREMA showcases its latest developments across all application segments. For post consumer recycling, the Austrian manufacturer presents its VOLEX technology, which sets a new benchmark in terms of degassing performance, and celebrates its premiere at the K show.

Ansfelden/Düsseldorf, 8 October 2025 - The plastics industry agrees that the proportion of recycled materials used in new products needs to continue to increase in order to achieve our shared goal of a circular economy. At K 2025, EREMA demonstrates what is already possible and where this journey is taking us. "The progress made in plastics recycling is enormous. We have achieved an impressive number of successes together with our customers over the last few decades. As we drive innovation forward, EREMA still sets the trends in this industry," emphasises Manfred Hackl, CEO of the EREMA Group, at the opening of K 2025.

Experience plastics recycling in action - from washing input material, to finished pellets

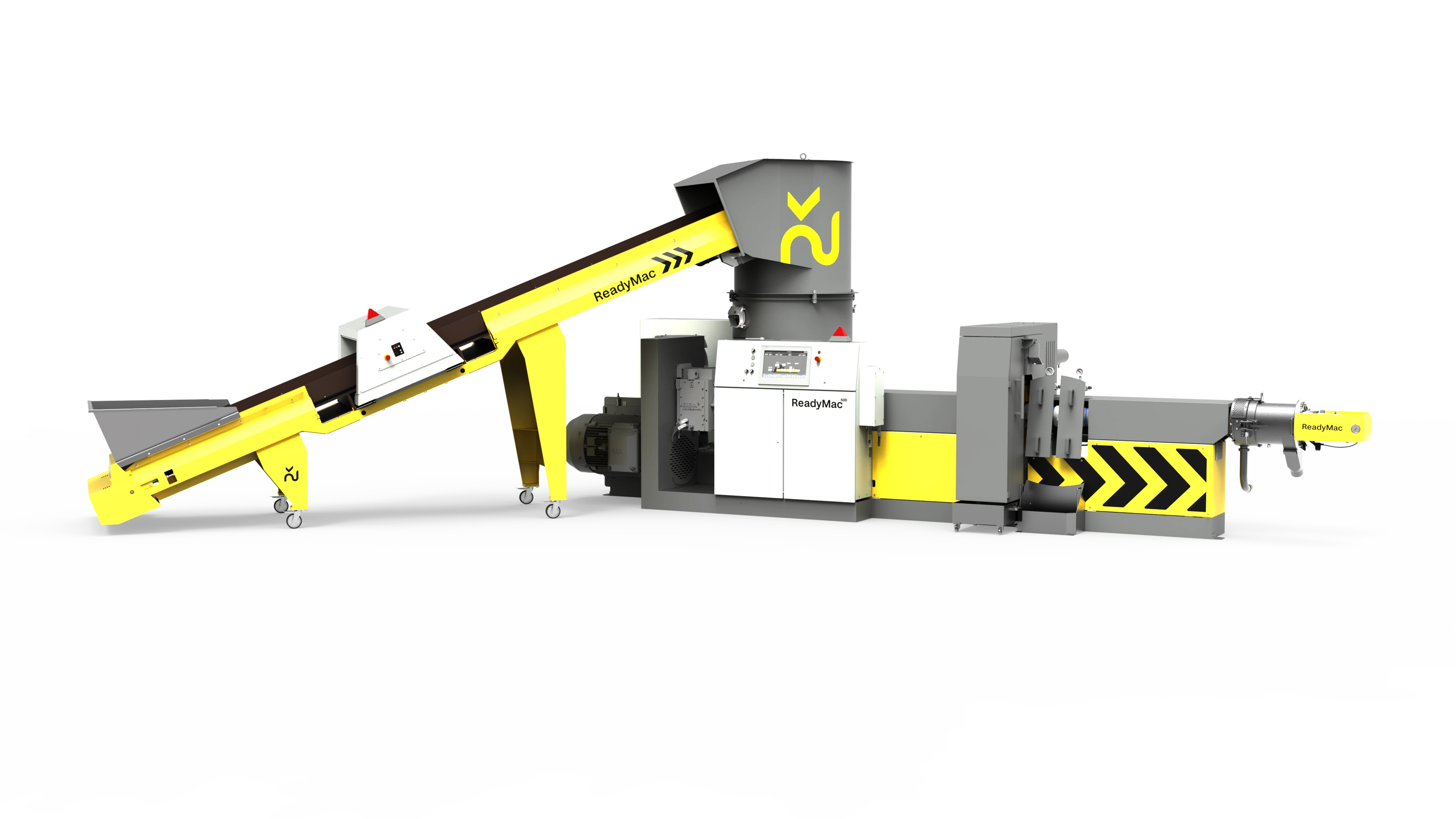

In the Edvanced Recycling Centre at outdoor area C03, EREMA is working together with customers and partners to demonstrate the wide range of applications in which recycled pellets are already being used. 60 products containing up to 100 per cent recycled material are on display, ranging from food-safe HDPE bottles and cosmetics packaging to transport films and lifestyle products. Some of these products are made from plastic waste that is recycled during the trade fair. An INTAREMA® 1108 TVEplus® DuaFil® Compact processes eleven different materials in a total of 15 test runs. ReFresher technology for odour-optimised premium pellets, which has been established on the market for many years, is also an integral part of the processes being demonstrated.

A Lindner Washtech washing system is located right next to the EREMA extrusion line, as the joint venture partners demonstrate a well-matched end-to-end process. The HMI developed by the two companies visualises the networked data of the two systems and the ReFresher in an intuitive dashboard. The precise interaction of the full process chain is a critical factor for creating more efficient recycling processes to increase the quality of the recycled pellets. A real-life example is on display at the Edvanced Recycling Centre: Polymer Matters in Ireland turns HDPE milk bottles from household recycling schemes into food-grade recycled pellets that are used to make new HDPE milk bottles.

Higher degassing and digital solutions for more cost effectiveness

EREMA's ongoing investment in research and development is what secures its technological leadership. The company has innovations in all its five industry segments (inhouse & industrial recycling, post consumer recycling, bottle recycling, fibre & textile recycling and chemical recycling). One of the focuses is on post consumer recycling, and Markus Huber-Lindinger, Managing Director at EREMA, presents the latest innovation here: "Our VOLEX technology sets new standards in extrusion. This is the first time that the water stripping process has been implemented highly effectively on a single screw extruder. Made possible by the unique plus zone of the INTAREMA® TVEplus® in combination with a specially developed extruder screw and cylinder geometry, it also features an intelligent dosing and control concept. Ultimately, we can now significantly increase degassing performance and open up new business opportunities for our customers."

For recycling companies, it is the quality of the recycled pellets as well as the availability of the machine that determines commercial success. "An avoidable cost factor at production plants is a machine that is at a standstill," says Huber-Lindinger. "We support our customers with a comprehensive range of services, rapid spare parts availability, and intelligent assistance systems, to keep machine downtime to an absolute minimum." At the K show, EREMA is launching two more modules for the PredictOn predictive maintenance series: AI-assisted data analysis, and condition monitoring for the plastification unit. Both modules are installed on the INTAREMA® machine at the Edvanced Recycling centre and can be monitored live using the BluPort® screen at the trade fair stand. "The BluPort® digital customer platform brings together all apps and data intuitively in one place. This gives our customers all the information they need to make informed decisions and optimise the performance of their machines at any time. It is this level of extensive functionality that makes BluPort® unique in the industry," says Huber-Lindinger.

Focus on young talent

Although the geopolitical situation is putting the brakes on the motivation for many companies to invest, there is no way around plastic recycling in the medium term. That is because the demand for plastics continues to grow worldwide. "In terms of social development, we need application-specific recycling solutions, with secondary raw materials playing an increasingly important role in Europe," says Hackl. Shaping this future requires the right technology, as well as dedicated professionals. Encouraging young people with talent is important to EREMA. "We are pleased that Jacob Manhartsgruber, who is a highly motivated young member of EREMA, is part of the Young Talents initiative," says Hackl. Manhartsgruber completed training as a machine and operating systems technician at EREMA and is attending the K show to explain the opportunities and possibilities offered by the plastics industry to young people.

Edvanced Recycling powered by EREMA

The current campaign Edvanced Recycling - EREMA prime solutions for advanced recycling sees EREMA present a wide range of advanced plastics recycling solutions. More than 40 years of experience, combined with practical application expertise, are the basis for EREMA systems consistently delivering high-quality recycled pellets to meet precise quality specifications, from food and cosmetic grade to more straightforward applications. Edvanced Recycling shows how EREMA is working together with its customers to sustainably increase the proportion of recycled materials used to make new plastic products. All the information is available online at edvanced.erema.com

Find out more and visit EREMA at K 2025: Hall 9, Stand: C09

and at the Edvanced Recycling centre: Outdoor area, CE03

Manfred Hackl, CEO of the EREMA Gruppe, and Markus Huber-Lindinger, Managing Director at EREMA, officially open the Edvanced Recycling centre at K 2025. A INTAREMA® 1108 TVEplus® DuaFil® Compact demonstrates the recycling of 11 different input materials during the trade fair.

Photo credits: EREMA GmbH

Rückfragehinweis

Julia Krentl

Corporate Communication

EREMA Group

Unterfeldstraße 3

4052 Ansfelden, AUSTRIA

Phone: +43 732 3190-6092

E-Mail: public.relations@erema-group.com