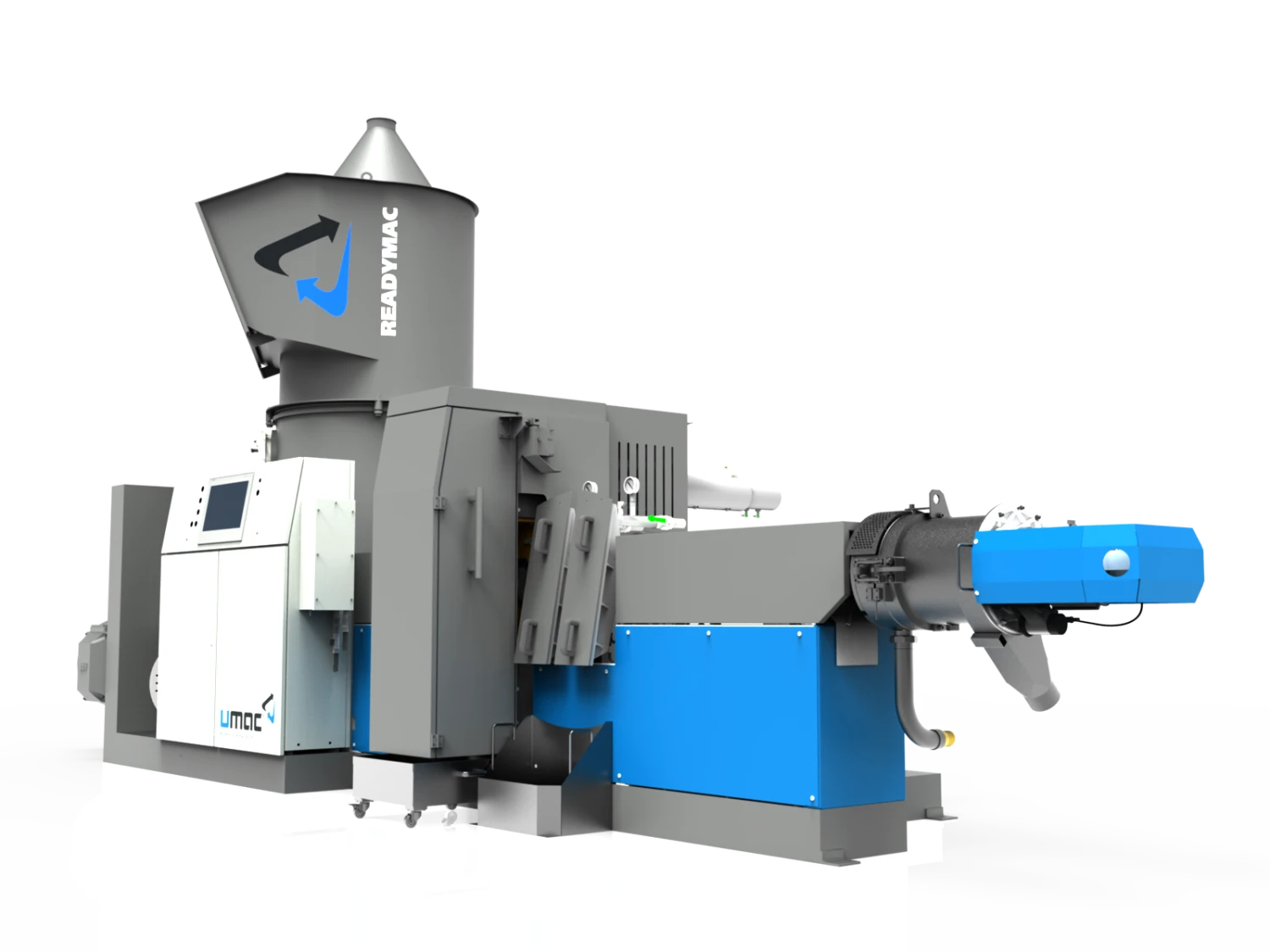

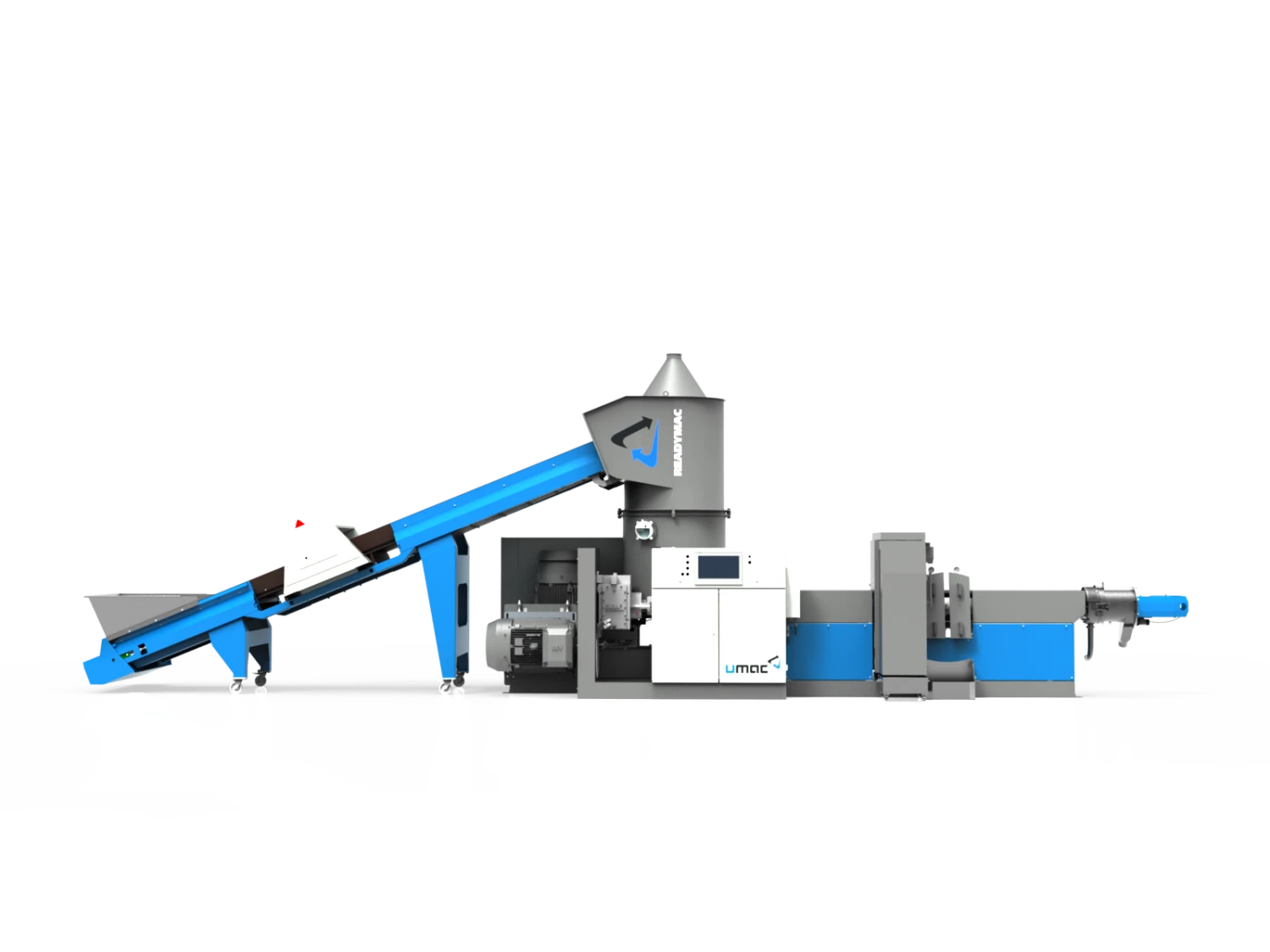

UMAC expands its business scope. Now, the EREMA Group company is offering not only previously owned, customised plastics recycling machines, but also a new machine that is made to stock and is therefore readily available at short notice. Launched at K 2022, the READYMAC system handles many standard applications in the post consumer recycling segment and is an attractive option for customers who need a recycling solution at short notice without custom configuration.

READYMAC 1109 TVE is a standardised machine based on EREMA's proven TVE technology. Equipped with a robust SW RTF® screen changer filtration system from EREMA's POWEFIL business unit, it processes printed inhouse input streams as well as post industrial and lightly contaminated post consumer waste material. Throughput capacity is up to 450 kilograms per hour. "If customers are looking for a recycling machine for standard applications that is available immediately, we can now offer them a new product that represents excellent value for money, in addition to our range of previously owned equipment," says Markus Stölnberger, Managing Director UMAC GmbH.

"If customers are looking for a recycling machine for standard applications that is available immediately, we can now offer them a new product that represents excellent value for money, in addition to our range of previously owned equipment"

The READYMAC plastics recycling machine is produced at the company's location in St. Marien (Upper Austria). While all the other machines in the EREMA group of companies can be configured to meet customer requirements, READYMAC is supplied as an unchangeable standard version without any further options. The first production series has been designed to operate using the mains voltage available in Europe (240/400 V; 50 Hz). "We have designed the machine based on our many years of experience so that it is suitable for different input streams such as polyethylene, polypropylene, polystyrene, polycarbonate and polyamide (PA 6). The TVE technology with degassing and the SW RTF® filtration system with its backflushing mechanism ensure a very high pellet quality that meets the criteria of a very wide range of standard applications," explains Stölnberger, which is why UMAC is now launching a new business unit to focus on this segment. Customers benefit from this in several ways: READYMAC is made to stock so that the machine can be put into operation within a very short time, regardless of where it is installed.

Proven EREMA technology

Both the TVE technology and the filtration system featured on this machine have been tested many times because the TVE technology comes from the sister company EREMA and the filter from its POWERFIL business unit. Both have a proven track record for reliability, operability, and quality in widely differing conditions at recyclers around the world. In terms of cost effectiveness, the new READYMAC delivers impressive value for money. For commissioning and service, the experts at UMAC and EREMA are also reliable partners for this new machine. All this makes READYMAC an interesting alternative for customers looking for a recycling solution that is available at short notice and at a reasonable price.

Visit UMAC in Hall 09, Stand 9C09

Download press release as .pdf:

Download picture as .jpg: